Update Your Fleet: Quality Screener for Sale at Competitive Rates

Update Your Fleet: Quality Screener for Sale at Competitive Rates

Blog Article

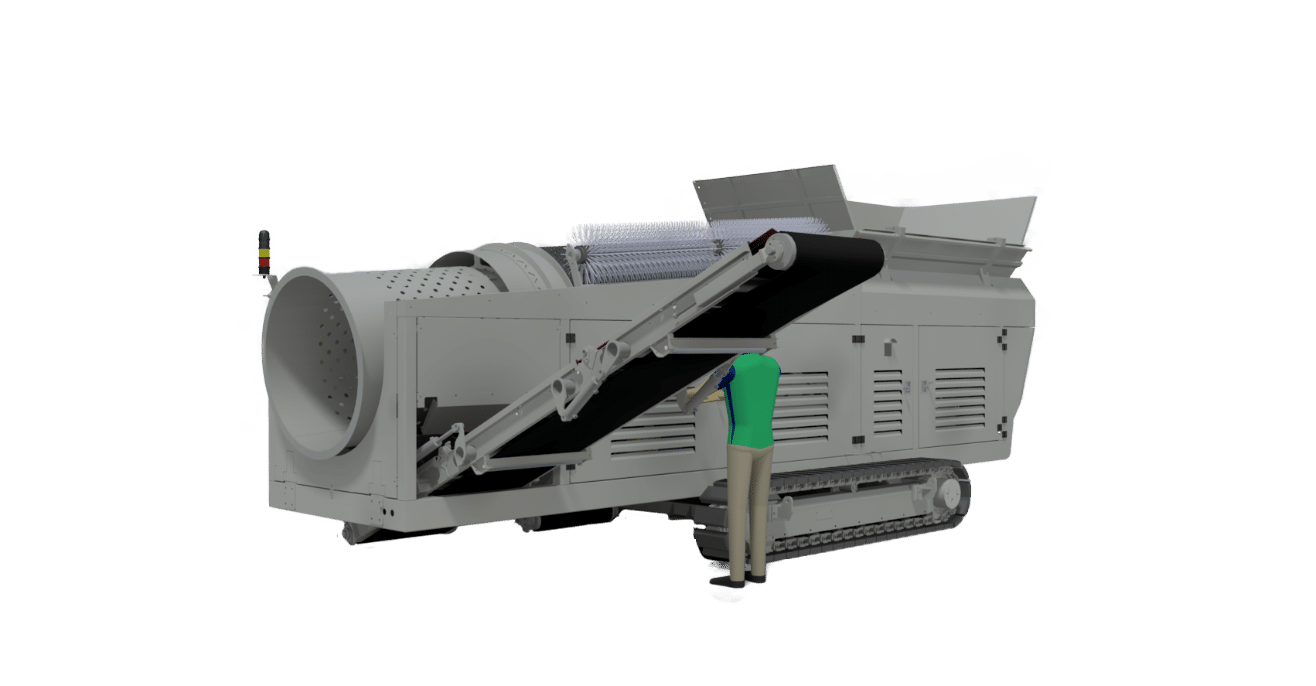

Make The Most Of Recycling Output With State-Of-The-Art Screener Devices

Benefits of State-of-the-Art Screeners

Modern screeners provide various advantages in the recycling market, helping with accurate and effective separation of products. One of the crucial advantages of state-of-the-art screeners is their capability to improve the overall performance of the reusing procedure.

An additional advantage of these screeners is their high degree of accuracy in material separation. Making use of sophisticated sensing units and formulas, they can exactly recognize and divide various materials based upon their form, structure, and size. This makes sure that the last recycled items fulfill the required top quality criteria and can be used in different markets.

Cutting edge screeners likewise add to the ecological sustainability of the recycling market. By effectively dividing materials, they reduce the quantity of waste that goes to garbage dumps and boost the quantity of recyclable products that can be reused. This not only saves beneficial sources but also decreases the carbon footprint connected with the production of brand-new products.

Secret Attributes to Look for in Screener Equipment

When choosing screener devices for recycling, it is vital to think about key features that improve effectiveness and accuracy in material separation. These features can dramatically impact the overall efficiency of the reusing procedure and maximize the result. One crucial function to look for in screener devices is flexible testing angles.

Various materials call for different screen sizes and styles to attain efficient splitting up. It is critical to select a screener that uses a variety of screen media choices to suit the diverse variety of materials in the recycling stream.

Finally, progressed automation and tracking capacities ought to be considered. Attributes such as remote tracking, real-time diagnostics, and data evaluation can significantly enhance the performance and efficiency of the screener tools. These features make it possible for drivers to identify and attend to any type of issues without delay, optimize operations, and optimize recycling result.

How to Select the Right Screener for Your Recycling Facility

To pick the proper screener for your recycling center, mindful consideration of crucial elements and certain demands is essential. The very first action in selecting the right screener is to examine the type and quantity of material that will certainly be refined.

One more crucial variable to consider is the preferred outcome size. Screeners come with different mesh dimensions, which determine the size of the fragments that can travel through (screener for sale). It is important to pick a screener that can achieve the desired bit dimension array for your specific recycling procedure

The capability and performance of the screener should additionally be taken into consideration. The throughput ability must match the volume of product that needs to be processed within an offered timeframe. In addition, the effectiveness of the screener in separating the wanted materials from pollutants is essential for maximizing reusing result.

Furthermore, the maintenance requirements and functional prices of the screener must be assessed. Look for screeners that are easy to tidy, maintain, and fixing, as this will assist decrease downtime and boost performance.

Tips for Making The Most Of Effectiveness With Screener Devices

One key technique for maximizing performance with screener equipment is to regularly tidy and keep the screens. Over time, screens can come to be clogged with particles, minimizing their effectiveness and slowing down the screening process. By applying a regular cleaning and upkeep routine, operators can make sure that their displays are running at peak performance.

Cleansing the displays entails removing any kind of accumulated material or particles that might be blocking the mesh. Routine examinations ought to additionally be carried out to identify any kind of signs of wear or damages to the screens.

Real-Life Success Stories of Recycling Facilities Making Use Of State-of-the-Art Screeners

Numerous reusing facilities have actually attained impressive success by integrating advanced screeners into their operations. These real-life success tales highlight the positive effect that advanced screening equipment can have on recycling centers.

By spending in state-of-the-art screeners, the facility was able to considerably boost its reusing output. The screeners were able to effectively separate different kinds of recyclable products, resulting in a higher top quality end item.

One more reusing facility in a rural location additionally experienced excellent success with state-of-the-art screeners. The facility had been battling to successfully sort and separate recyclable products, resulting in a decrease in article productivity. Nevertheless, after including innovative screeners into their procedures, the center saw a substantial enhancement in its reusing outcome. The screeners were able to accurately and effectively type products, leading to a more structured procedure and boosted performance.

These success tales demonstrate the importance of investing in advanced screeners for recycling facilities (screener for sale). By including advanced screening devices, centers can optimize their recycling result, rise profits, reduce waste, and add to an extra sustainable future

Final Thought

In final thought, modern screener tools supplies countless advantages for reusing centers, consisting of boosted recycling outcome and enhanced efficiency. By thinking about essential features and choosing the right screener, facilities can maximize their reusing efforts. In addition, applying pointers for making the most of effectiveness can better enhance the effectiveness of screener tools. Real-life success stories highlight the positive impact of making use of cutting edge screeners in reusing facilities, making them an essential device in the recycling sector.

Modern screeners provide numerous benefits in the reusing market, about his facilitating reliable and precise separation of materials.When picking screener devices for reusing, it is important to consider crucial features that boost efficiency and accuracy in material splitting up. It is essential to pick a screener that offers a selection of screen media alternatives to fit the varied array of materials in the recycling stream.In conclusion, state-of-the-art screener tools offers numerous benefits for reusing centers, consisting of raised reusing result and improved effectiveness. Real-life success stories highlight the favorable influence of utilizing advanced screeners in reusing centers, making them a necessary device in the reusing industry.

Report this page